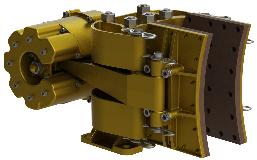

5025-SH SPRING APPLIED HYDRAULIC RELEASED CALIPER DISC BRAKE

Kobelts 5025-SH spring-applied hydraulic released caliper disc brake is built entirely of bronze and stainless steel. It is providing a solid, long-lasting braking solution for even the harshest environments. These caliper disc brakes are well suited for parking or emergency braking duty on draw works, hoists, winches and more.

The 5025-SH spring brakes comes in several different mounting configurations, matched well to Kobelt’s 4″ (102 mm) and 7″ (178 mm) ventilated discs. With a minimum 25″ (635 mm) diameter, and a maximum disc diameter of 86″ (2.184 mm). The SH caliper disc brakes allow for integration into higher PSI systems.

All Kobelt brake models are designed to reduce the burden of ongoing service and maintenance which minimizes the overall cost of ownership.

All Kobelt caliper brakes can be fitted with either air applied, hydraulic applied, spring applied with air released or spring applied with hydraulic released actuators depending on the required service.

INSTALLATION

The foundation plate to support the brake caliper must be designed to withstand the maximum braking forces generated by the brake caliper. It must also be flat to ISO tolerance grade IT8 and square to the brake disc. A brake pedestal must be designed to allow the mounting bolts to be inserted from underneath. The rotating element should have bearings sufficient to carry the weight of the disc. It also resist the additional stress when the disc brake is applied. The spigot that centers the brake disc must not be designed in such a way that it impedes the thermal expansion of the disc.

Any guarding around the brakes must provide enough room to allow full extension of the brake

actuators plus full pad wear adjustment.

The piping to the brakes must be adequately sized to ensure rapid response times in all weather conditions. The piping must be selected to safely withstand the pressures required to operate the brakes.

For all Kobelt brakes are repair kits available.